How

we test

our products

Features

The competitive advantage of our approach is the continuous improvement of the quality of materials. Our specialists from the R&D department are constantly collecting feedback from our customers and working on improving and adjusting the product to make TRIVENT® textile even better, more competitive, and environmentally friendly.

How we test our products

- We use our own technological, testing, and analytical equipment, which allows us to conduct comprehensive researches on membrane textile materials. We determine vapor permeability by JIS L 1099 A1 and JIS L 1099 B1; water vapor resistance by ISO 11092; air permeability by ASTM D737, ISO 9237; water column by ISO 811 and JIS L 1092; physical and mechanical characteristics by ISO 13937 and ISO 13934; surface morphology of the membrane material.

- It is practically impossible to recreate all potential life situations in laboratory conditions. Therefore, our employees test the product in real conditions where it will be applied: on the mountain peaks or windy streets of the city.

Breathability

It is one of the most important performance characteristics. Our testing facilities allow us to measure breathability according to JIS L1099, ASTM E96, ISO 11092.

Waterproofness

With our TexTest HydroTester, we can measure water-resistance value in accordance with ISO 811 between 800 and 40000 mm w. c.

Air permeability

To confirm the windproof level of our materials we use TexTest FX 3300 equipment which shows how wind can permeate through the textile according to ASTM D737.

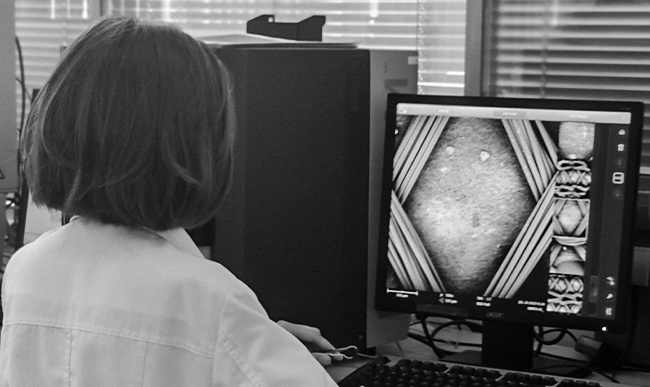

Surface morphology of the membrane material

The morphology of the nanofibrous membrane can show the quality of the production process and also it reflects the way fibers are formed.

All our products

are certified

and first-class quality

are certified

and first-class quality

Next

About Trivent